Cutting the molds with a CNC

Thanks to the CNC of my school's FabLab i could easily cut my molds directly from wood. I chose to do them from MDF because of the my budget. I hoped it would be strong ans stiff enough

Cutting the shapes

Thank you Paul Gaucher for helping me cut this infinite number of rectangles as well as all the sanding you did !

CNC cutting

After beaing properly attached i started the cutting which was in two phase:

First the CNC rouglhy removes the excess of wood, and then it starts the parallel phase which is more precise

Machining with Autodesk Fusion

Catia has a Machining component however I couldn't get it to work with the CNC. I used Autodesk Fusion to Genereate the GCODE that the CNC reads.

I found Fusion very easy to use and yet powerful.

From simulation to reality

The CNC cut the fuse exactly how i told it to do with the Gcode. The stepover of the parallels was set on 1mm with a flat-end-mill of 6mm

Strengthening the molds

The MDF wood didn't haave a good surface finish and could be polished directly

I added a layer of waterpox epoxy for it to be polished more easily

Surface Finish

To have this surface finish it took me at leat 3 hours of sanding per mold

And I had 14 of them...

Sanding and polishing

To have a nice surface finish I sanded the molds with 240,400, 800, 1200 sanding paper

Before the 800 I applied several layers of the S120 mold sealer and sanded again and again between the layers

I finished by polishing the mold with a polish compound

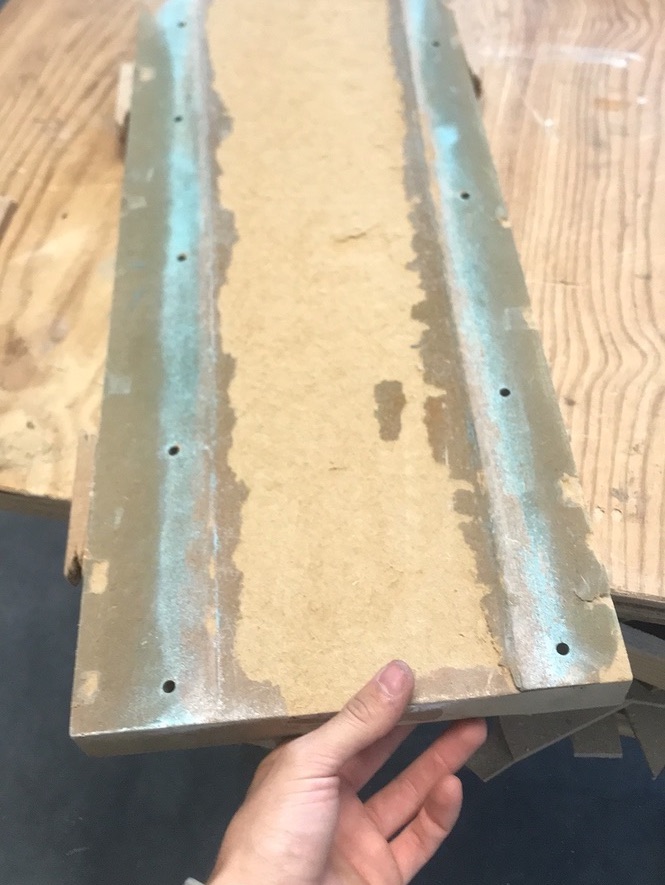

But the MDF wasn't strong enough..

After having finished EVERY mold I decided to test one

The mold release wasn't enough for the mdf not stick to the carbon..

I had to find another way

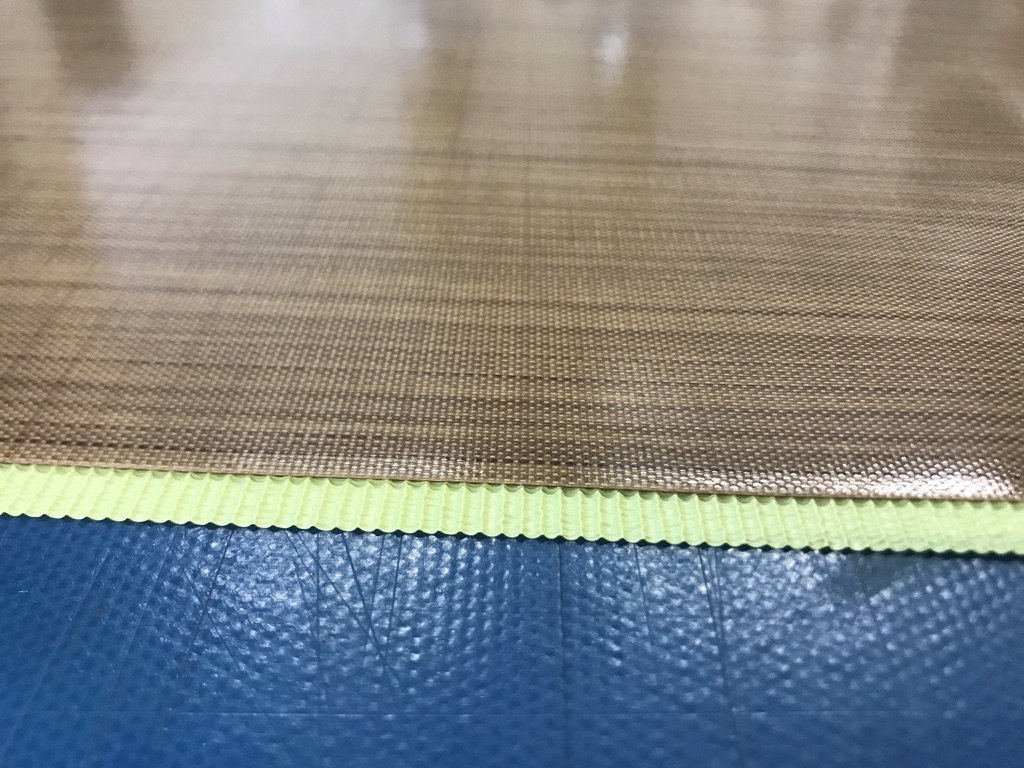

Adding a layer of Nylon

The Department of structure of my school gave me a roll of Nylon to put on the molds. The result is just perfect, I didn't even need a mold release! I should have done this from the start to gain more than 50 hours of work...

I will surely use this material in the future however it does need to be on developpable shapes wich is almost the case with the wings but not with the fuselage nor the winglets.

For the fuselage I used an expandable sticky tape of Nylon

The molds before the Nylon layer

You can see almost all the molds but the V-Tail molds are missing on this picture

How it looks with the Nylon

Even though the shape of the mold of the exterior wing with the winglet is not developpable i've put a layer of Nylon which does extend just enough to take the shape of the mold